The ultimate in bluewater cruising sail material is Hydra-Net Radial from Dimension Polyant Sailcloth.

Hydra-Net was first produced in 1999 as a cross-cut/radial cut balanced weave material with 7% dyneema content. In 2003 the specialist radial version with 45-55% dyneema content was released which is now our favorite cruising material. Dimension Polyant was the first sailcloth manufacturer to master the technique of weaving heat sensitive dyneema with normally heat shrunk polyester together into woven sailcloth. Hydra-Net was used by the early Open 60 Vendee globe racing yachts due to its super durability, but has since become a favorite option for long distance cruising sailors. Hydra-Net combines good shape holding, exceptional tear strength, breathability and non molding with a super long sail lifespan. One sail exhibited by dimension polyant had sailed over 240,000 miles which shows the outstanding longevity that is achievable with this material. One of the challenges of making sails with Hydra-Net is making sure every other part of the sail will last as long as the sailcloth!

Zoom Sails is one of the largest users of Hydra-Net Radial and have a wealth of experience designing and building sails using this material

Hydra-Net was first produced in 1999 as a cross-cut/radial cut balanced weave material with 7% dyneema content. In 2003 the specialist radial version with 45-55% dyneema content was released which is now our favorite cruising material. Dimension Polyant was the first sailcloth manufacturer to master the technique of weaving heat sensitive dyneema with normally heat shrunk polyester together into woven sailcloth. Hydra-Net was used by the early Open 60 Vendee globe racing yachts due to its super durability, but has since become a favorite option for long distance cruising sailors. Hydra-Net combines good shape holding, exceptional tear strength, breathability and non molding with a super long sail lifespan. One sail exhibited by dimension polyant had sailed over 240,000 miles which shows the outstanding longevity that is achievable with this material. One of the challenges of making sails with Hydra-Net is making sure every other part of the sail will last as long as the sailcloth!

Zoom Sails is one of the largest users of Hydra-Net Radial and have a wealth of experience designing and building sails using this material

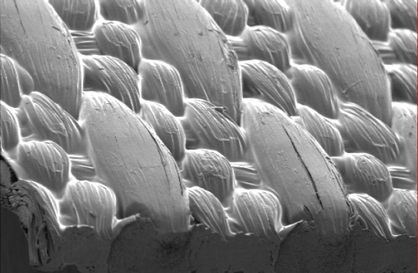

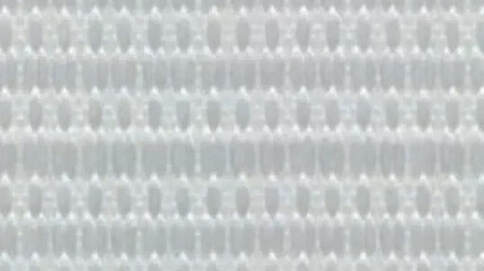

In a cross-cut sail the panels are cut across the roll using the straight weft fibers in the high load direction of the sail. Radial cut panels are cut down the roll length using the warp yarns which go over and under the weft fibers. When load is applied, the warp fibers stretch out and straighten, something that is not desirable for sail shape. The way Hydra-Net radial reduces this "crimp" in the warp fibers is seen in the close up photos below. The big ultra PE yarns can be seen coming out of the weave and passing over weft yarns, before entering back into the weave, thus reducing the crimp in the fibers, and stretch in the sail when load is applied. This requires special weaving looms which Dimension Polyant has developed in house with their German sailcloth factory.