|

In this article we will look into some of the common downwind options for blue water cruising sails, and offer some advice on the advantages and disadvantages for each type of sail. Symmetrical SpinnakersThe classic downwind sail is the Symmetrical spinnaker. This sail is the same length on both long edges ( leeches ) and the aerofoil shape built into the sail is symmetrical, so it can be gybed by simply rotating the sail to the other side of the boat. The disadvantage of being a symmetrical aerofoil is it isn't as efficient when reaching, but this doesn't mean it can't sail the same angles as a Asymmetrical sail of the same entry angle and depth. Generally spinnakers are flown from a spinnaker pole to add stability, control and extra speed. They can be flown without a pole on catamarans or trimarans where they can be tacked onto each outer bow. We've also seen them flown from the bow of a mono-hull with a soft strap around the furled up genoa in light airs. The design scope is quite large, and for cruising they don't have to be maximum size and can also be made easier to trim though shaping. The Para-Sailor type sail is a Symmetrical spinnaker with a cut out and wing in the center which acts like a soft batten, thus making the sail more stable. The cut out also helps to dampen the effect of gusts. The marketing on these sails is a little over the top, but they do offer some advantages to the cruising sailor over the traditional spinnaker. One of our customers who has both on his 50ft catamaran said "It isn't any easier, but it is more stable in high winds". Traditionally cruising spinnakers have been made from Nylon ranging from 0.5oz to 2.5oz. For cruising a snuffer sock is often added to make hoisting and dropping safer and easier. The advantages of a Symmetrical spinnaker are speed downwind - they project a large amount of sail area. They are versatile when used with a rotating pole, but the pole requires a downhaul and uphaul to keep it stable so there is a lot of rigging involved. Reaching they also project a large area, but the shape of the sail is not as efficient as an Asymmetrical sail. Asymmetrical SpinnakersAsymmetrical spinnakers started becoming more popular in the mid 90's and have become the most common downwind cruising sail. The luff on a asymmetrical spinnaker is longer than the leech and the foil shape is asymmetrical allowing more efficient reaching when the wind is flowing over both sides of the sail. Asymmetrical spinnakers can be flown from a pole off the mast just like a spinnaker, but are generally tacked onto the bow, or flown from a bowsprit. On Catamarans they can be tacked to the windward bow to allow running at deeper angles when used together with the mainsail. When tacked onto the bow of a mono-hull, if you are sailing too deep downwind, the sail will lose the wind as it comes into the wind shadow of the mainsail. Some cruisers prefer to sail without the mainsail which allows running dead downwind. On faster boats a zig zag course can become a faster way to sail downwind as the boat brings the apparent wind forward. But on most cruising cats and mono-hulls it is still faster to go with the wind, if that is the direction of your destination. Asymmetrical spinnakers can also be varied in size, width and design based on the type of boat, and the type of cruising. As with symmetrical spinnakers the fabric used is normally Nylon, and for cruising ranges from 0.75oz to 2.5oz Asymmetrical spinnakers for cruising have traditionally been paired with snuffer socks for hoisting and dropping. In the last few years top down furlers have started to become popular. The top down furler works by allowing the tack of the sail to swivel and wrapping the sail around a soft torsion rope from the head down. An asymmetrical spinnaker purposely designed for furling will have softer corners, and a flatter cut, but it is still okay to retrofit an old sail to a top down furling unit. The advantages are it is easier to setup tacked onto the bow, without a pole off the mast. They can be used with a furler, although some people still prefer the sock. They are fast reaching, but can't go dead downwind when tacked on the center line and the mainsail is hoisted. Cruising Code Zero and ScreecherIn the last few years the Cruising Code Zero's have been growing rapidly in popularity. These sails are not as big in size as spinnakers or as fast beam reaching and running, but are versatile and easy to handle for the cruising couple or family. They are also made of more durable and slighter heavier material than a spinnaker and work on furlers with a soft torsion rope inside the luff of the sail. Code Zero's are still made from a variety of fabric options from different sailmakers. We prefer a ripstop polyester which offers better performance and UV resistance than Nylon, while being more durable and longer lasting compared to the laminated cloth options available. Code zeros are at their best reaching forward of the beam, but also work well beam to broad reaching and can be poled out downwind to give maximum projected area and stability. A screecher is a term that comes from multi-hulls and is a similar sort of sail/concept. With their increased righting moment catamarans are able to carry these sort of sails in higher wind strengths, so the sails are a little heavier built, and in some cases are used to increase performance to windward in light airs, which requires a flatter cut. Drifter is also a term that should be mentioned, as these were similar to what we call a cruising code zero now a days. They are a big light air polyester genoa, that was generally either hanked onto the forestay or an extra stay in front of the forestay. The advantages of the code zero style sails are that they are more durable and forgiving than a spinnaker, easier to trim with the straight luff and internal torsion rope. Disadvantages are they can become heavy on bigger boats, and because the size is not as great as a spinnaker they are not as fast deeper reaching or running . Twizzel rig and other wing/wing downwind optionsThe twizel rig has been around for at least 50 years and is still an option for people sailing trade wind routes. Basically it is twin identical head sails, with one out each side and used without a mainsail. One or two poles add stability and you have a pretty durable downwind setup for medium to strong winds. In recent times this option has moved to twin furling headsails, so both sails can be reduced in size from the cockpit. You can also sail with both sails on the same side if needed. A recent variation of this concept, has been to make twin code zeros flown from an endless line furler and soft stay. This offers advantages in light airs, where you can increase the sail area over more traditional headsails, but you lose the ability to reef, as it is either all the way in or out. But it does also give you a code zero, as you can fly both sails together on one side for reaching We have also seen twizzel style setups with sails on different stays, either a large staysail or solent and the genoa, or even a code zero and a genoa. Sailing downwind without the mainsail, the boat is actually quite well balanced with the center of effort further forward, and the tendency to round up reduced. As a boat comes further off the wind, the center of effort of the sails needs to be further forward to balance the boat. That said there is nothing wrong with the standard working sail setup of mainsail with preventer and poled out genoa. A lot comes down to personal preference and what you are used to, and comfortable with. I hope you enjoyed this article. For future articles and updates, please like our facebook page.

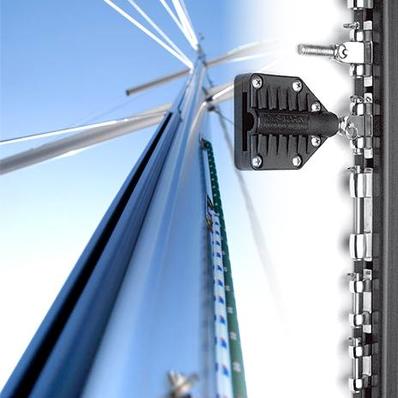

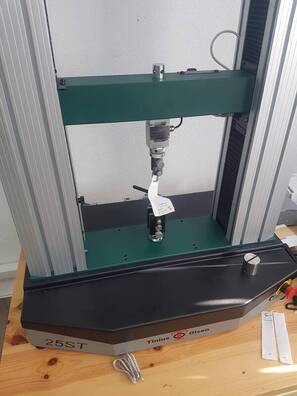

The purpose of these articles is to inform cruisers of potential sail problems associated with bluewater cruising. Sail repair services in remote locations can be non-existent so sail reliability is key to a safe and stress free journey. Luff Hardware - Standard Sliders Plastic slider or shackle failure is a common problem we see. In a heavy squall or while dropping the sail in heavy air, one slider failing can cause the rest to "pop" resulting in a flogging, out of control sail! It is advisable to use the strongest plastic sliders available for each mast track. We use fiber reinforced plastic sliders or plastic coated metal sliders where possible. Un-coated metal sliders will almost never fail, but can cause wear on the mast track over thousands of miles. Sometimes there is no other option due to the type of mast track and size of sail. Attaching the sliders to the sail with plastic shackles can reduce some friction but isn't recommended as the shackles are prone to breaking with age, sun damage or excessive load. Attaching the sliders with webbing on to the luff is preferred. The trend with racing sails has been to machine sew the slider to the sail with webbing straps. Some sailmakers have carried this over to cruising sails. While this simplifies the manufacturing process, if a slider does fail it is not possible to replace the slider without a sewing machine, which of course involves removing the sail. The preferred method for blue water sails is to attach the slider to the sail with webbing though an eyelet on the sail or slot in the batten box. This is the strongest connection and if a slider does break it is possible to replace it yourself at sea with the hand sewing needle and thread found in the sail repair kit, or with a simple 2mm rope lashing. Low Friction hardware Low friction hardware can be broken down into two categories, using the existing mast track or installing an extra external track attached to the existing track. 1. Existing track hardware Rutgerson wheeled low friction sliders - Either used only on full battens or on intermediate sliders. For certain mast types the wheeled sliders do a good job of reducing friction. Ronstan Ballslide system The Ballslide system does a good job of reducing friction via bearings running on the back surface of the mast. Once again, this system is only compatible with certain mast models. It is more expensive than the Rutgerson Sliders. For both systems we need highly accurate measurements to determine compatibility. Also of note is sometimes the presence of a close trysail track prevents these sliders being used. 2. External track hardware Tides Marine Strong track A very popular cost effective solution for blue water cruisers. A low friction strong plastic track is slid up the existing sail track. This system is compatible with almost any existing mast track. The sliders are all S/S. The plastic track will last 10-15 years at which time it can be replaced, while the sliders can be reused. We have used this system on up to 60ft mono-hulls and 45ft Catamarans. Ronstan and Harken external bearing systems Ronstan and Harken both make external track systems that attach to the mast's existing sail track. They use cars with low friction torlon bearings and when sized correctly are very strong and low friction. Cost is quite high but for boats over a certain size this is the only solution. These systems work very well but do wear out eventually. Other types of external track. A few other types and brands of car systems do exist, for example the Antal, Facslide, etc. Each have advantages and disadvantages with a varied price. Normally a local rigger will advise his preferred system. Sailcloth Part 2 - Dacron and woven HMWPE With so many different dacrons available it is hard for the sailmaker, let alone the customer, to figure out the good and the bad. Of course, if you read the marketing material every dacron is made to sound good. But the reality is quite different and only independent testing can shed some light on the true durability, UV resistance and quality of the fabric. Even between batches the quality can vary so most high quality sail producers test a sample from each roll to check it is up to standard; if not, it is returned to the cloth supplier. We have ongoing testing projects to find both the best dacron and the best value for money dacron. Stretch testing involves measuring the material stretch in three directions, the warp, the weft and the bias; in other words, up, down and diagonally. Dacron is the most stretchy diagonally due to only having fibers running in two directions. The diagonal stretch is controlled by the resin finish of the sail cloth. The harder the resin, the less diagonal stretch is present. Tightness of the weave also has an effect on diagonal stretch. However the disadvantage of a tight weave is that the yarns are smaller and so the cloth tears more easily. Smaller yarns are also more susceptible to UV damage than bigger yarns so the cloth will end up with a low tear strength a lot quicker than a material woven with bigger yarns. The firmness of the resin finish is a balancing act for cruising sails between performance and sail handling, especially for traditional slab reefing mainsails and hank on headsails. The harder the resin the harder the sail is to handle for the sailor. For this reason most cruising sails are made with dacron that has a medium finish - which still feels hard to most cruisers. Different resins break down at different rates so one of the ways we test dacron is to flutter the sample on a fluttering machine to see how quickly the resin deteriorates for each dacron sample. UV testing involves leaving samples in the sun and weather for months at a time and then comparing the dacron to identical samples kept inside out of direct sunlight. The same machine used for stretch testing is also able to measure tear strength of sun damaged and undamaged samples. Sailcloth - Woven HMWPE

Our most popular high performance woven material is Hydra-Net Radial by Dimension Polyant. This fabric is a woven blend of polyester and super strong hmwpe (dyneema/spectra) fibers. The reason for its popularity is it offers a more performance orientated sail, but without the molding or lamination issues of a laminated material in high humidity climates. It also outlasts performance laminated materials by at least two times. However the price is higher, so the material is more popular on bigger or more performance orientated cruising yachts. The purpose of this article is to make cruisers aware of potential sail problems associated with blue water cruising. In remote locations sail repair service facilities can be non-existent therefore sail reliability is very important. We spent three years as full time cruisers and as a sailmaker and designer I have helped fellow cruisers deal with various sail issues. In this way I've attained a very good understanding of the sail problems faced by cruisers over the years evaluating and repairing damaged sails. In this first article we’ll talk about UV damage as it is a prime cause of sail problems for cruisers. Sail Cloth The most common cruising sail cloth is still woven polyester (dacron) so we'll focus our attention here in this article. Dacron (polyester) sailcloth degrades at a steady rate in UV light and obviously should always be kept covered when not in use. Some tell tale signs that dacron is sun damaged are a yellow discoloration and a slightly furry look to the fabric surface. The fabric will also tear easily and small 2 or 3mm holes may appear. Before embarking on a long passage it is worth having a close inspection of your sails to identify any cloth problems. The more UV hours the dacron is subjected to, the more the strength loss. While dacron sailcloth may all appear to look the same to the untrained eye, there are at least 5 different manufacturers, each having 2-4 different grades of dacron in their range. Even with a lot of research it is still tough for the customer to know which cloth is high quality and which is low. We weather and stretch tested as many dacrons as we could with some surprising results. We found a massive variation in strength loss due to UV damage – up to 90% strength loss in 6 months for some fabrics, while others are as low as 30%. We put this down to the different types of polyester yarns used in the construction and the different resins/coatings used in the manufacturing process. We use Dacron with a fairly balanced weave as opposed to high aspect dacron. This avoids vertical tearing (as seen in above photo), high aspect dacron has most of its strength in only one direction. We only use dacron from trusted suppliers that has performed well in our UV testing. UV Cover stitching One of the most common problems is when the Sunbrella or Acrylic UV cover on genoas and furling mainsails separates from the sail due to stitching failure caused by UV damage. While some UV polyester threads will last well we typically see the stitching on the UV cover failing after 3-5 years in tropical sun. This can lead to the UV cover partly detaching and flogging apart. The dacron material of the sail is then subjected to 24 hour UV damage until the sail can be repaired. The solution is PTFE (Teflon) thread which is not affected by UV light and will outlast any fabric including Sunbrella. Sold under many brand names the most common being Gore - Tenara this thread has been around for many years, but is rarely used by sail manufacturers. We sew all our sail UV covers with this product and the extra cost of the thread is overall a big saving of money and headache later on. Corners

Another less common but more serious problem on furling sails is when the stitching and webbing holding the corner rings or loops to the sail degrades so that the corner fails. In the photos above the stitching has degraded to a point where if the sail corner was subjected to a strong load, the ring or pulley would separate from the sail. While we cover all our corner webbing with Sunbrella or UV material and sew it with PTFE Tenara thread, many sailmakers do not. Polyester thread can lose 50% of its strength after 1 year in the sun. Exposing the thread and webbing holding the corner ring (which is regularly taking hundreds of kgs of load) to constant UV is a really bad idea in a tropical climate. We've seen many of these webbings hand stitched or even riveted back on to the sail. The corner webbing is also susceptible to UV damage, so here we cover all webbing with polyester tube webbing or sunbrella. Mainsails and hanked on genoas are also susceptible to corner failure due to UV damage. So it is important to make sure their sail bags and covers completely cover the sail corners. We too often see the corners poking out the ends of the covers. I hope you enjoyed this article, and please like us on facebook for future articles and updates. |

|

Proud supporter of Sea Shepherd

|